Canadian company ALUULA Composites’ ultra-light and strong composites have been chosen by Thin Red Line Aerospace for future NASA lunar and Mars missions.

Materials that meet the requirements of space technology very well

Canadian company ALUULA Composites has just been selected by Thin Red Line Aerospace, which specializes in advanced equipment for critical applications for NASA’s future lunar and Mars missions. “Their unique range of technical properties combined with impressive strength-to-weight ratio specifications make ALUULA composites very well suited to the needs of aerospace technology,” said Thin Red. Line Aerospace President Maxim de Jong .

A process that allows for a large number of iterations

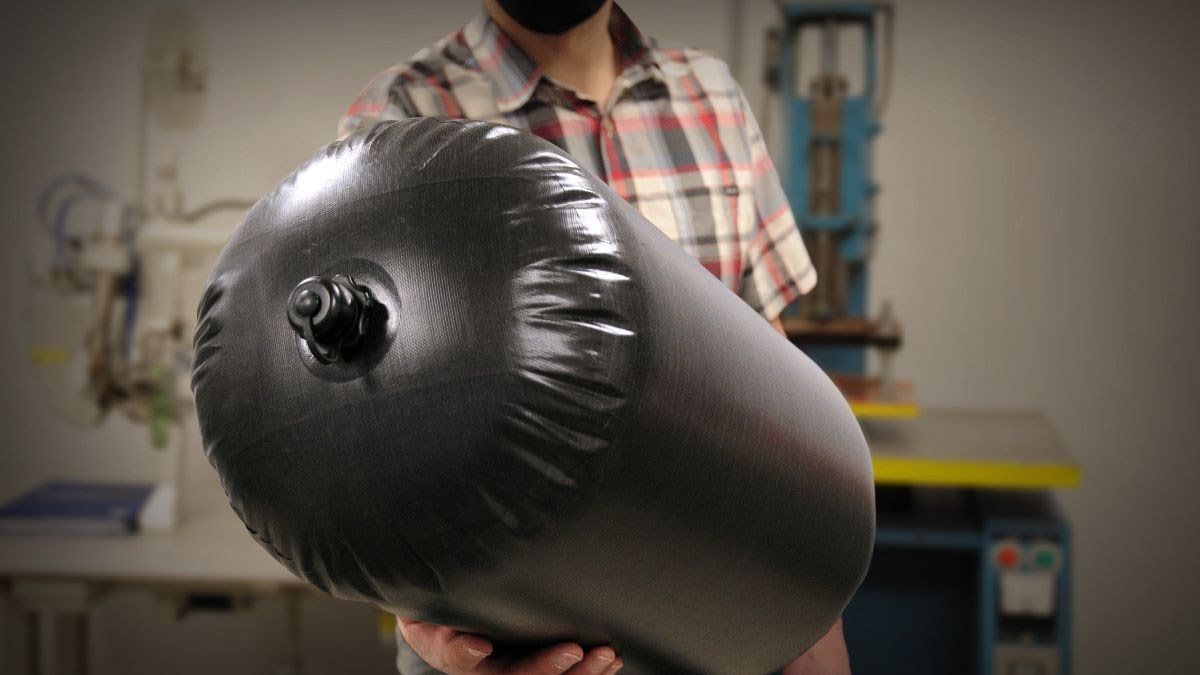

ALUULA Composites uses a patented fusion technology Combining foils with a UHMWPE core, resulting in a new generation of high-performance composites that deliver unique and superior performance results. This “process” rather than product perspective allows for a wide range of iterations to meet a wide range of applications. “We continue to find new and exciting ways in which our process enables and enhances composites to meet very specific engineering goals, and our work with Thin Red Line is another great example of what’s possible with our materials and unique expertise is,” said John Zimmerman, Deputy CEO of ALUULA Composites.

ALUULA is a new generation of composite materials composed of components with eight times the strength-to-weight ratio of steel, yet lighter than nylon, polyester or aramid. Using a patented fusion process, ALUULA Composites has developed a unique method of fusing high-tech engineered fibers and films without the use of heavy adhesives. By joining materials at the molecular level, ALUULA creates the lightest, strongest and most durable composite materials ever.

The result of an innovative combination of copolymer layers

ALUULA Composites is a Canadian company founded by a team of highly experienced chemists and engineers who share a common passion for exploration and outdoor activities. They have created a new field for shape-stabilized multilayer materials that are the result of an innovative bonding of copolymer layers, creating composites that are extremely lightweight, have high tear and stretch resistance, and are easily formed into a variety of products across a wide range of markets .

Extreme problem solver. Professional web practitioner. Devoted pop culture enthusiast. Evil tv fan.

;Composite=(type=URL,url=https://images.radio-canada.ca/v1/assets/elements/16x9/outdated-content-2021.png),gravity=SouthEast,placement=Over,location=(0,0),scale=1)